Drive technology for sun shading from Lock

In today's world, a modern facade has many tasks. It is not only the face of the building, but is also responsible for the indoor climate. Accordingly, the facade must be able to adapt to the changing conditions of light and shade, wind and weather.

Lock supports architects, planners and facade builders in the realisation of sophisticated facades with innovative yet economical solutions.

Drive solutions for customised design:

Lock drives offer customised performance for facade elements. With self-locking drives for sun shading, natural ventilation and smoke and heat exhaust ventilation systems (SHEVS), you can realise your design without compromising on functionality.

Quality "Made in Germany":

Lock stands out due to its 80% vertical integration and highly qualified employees. This guarantees the highest quality, customisability and minimum downtime, bringing you long-term benefits.

Perfect for:

- Natural ventilation and SHEVS

- Shading and light control

- Photovoltaics

- Special applications

Application fields

Lock drive systems are innovative technological solutions that are used in various application fields, such as solar shading slats, ventilation slats and sashes and flaps. These robust drive systems offer a reliable and efficient way to control the movement and positioning of these structures.

The advantages of Lock drive systems lie in their precision and durability. It provides a reliable way of automating the positioning of slats, sashes and flaps, which not only increases ease of use but also optimises energy consumption.

Drive systems from Lock make a significant contribution to improving the functionality and efficiency of sun shading, ventilation and industrial systems. It, therefore, also plays an important role in modern architecture and technology applications.

Drive system for sunblinds, customised to your needs:

Lock drive systems are used in sunblinds to automate their opening and closing mechanisms. Thanks to the precise control of the slats, it is possible to optimise their position depending on the amount of sunlight to regulate the amount of light entering the room and, at the same time, protect it from excessive heat.

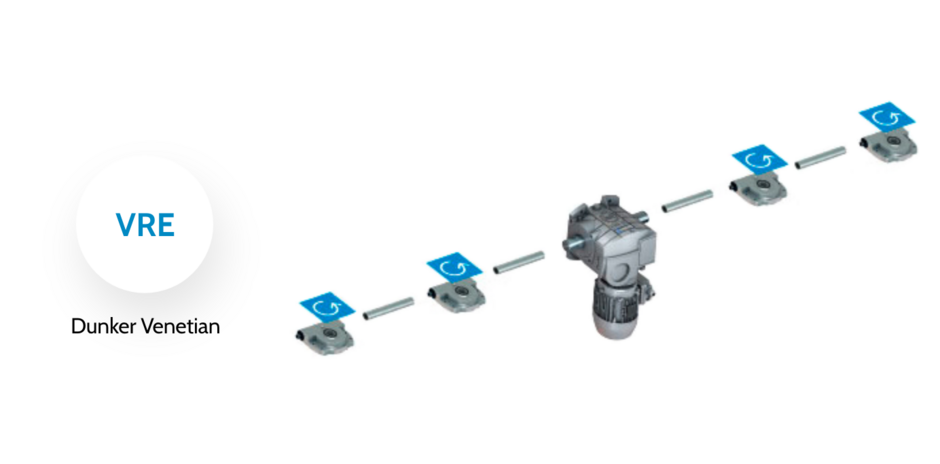

In this system in particular, two slats are combined to form a single unit, which is driven by a motor. Each slat is fitted with a high-quality VRE 76 worm gear, and by connecting both gears with a motor, the slats move in perfect synchronisation. This drive system was developed with maximum stability and reliability in mind.

The features include:

- Highly robust, self-locking special worm gearboxes.

- A sturdy aluminium housing that is fully sealed to withstand environmental influences.

- All external parts of the gearbox are made of stainless steel to ensure a long service life.

- A central drive for synchronising several gears enables the large-scale movement of slats.

- Minimal clearance, which ensures precise movement.

- Completely maintenance-free to minimise maintenance costs.

Drive systems for ventilation slats

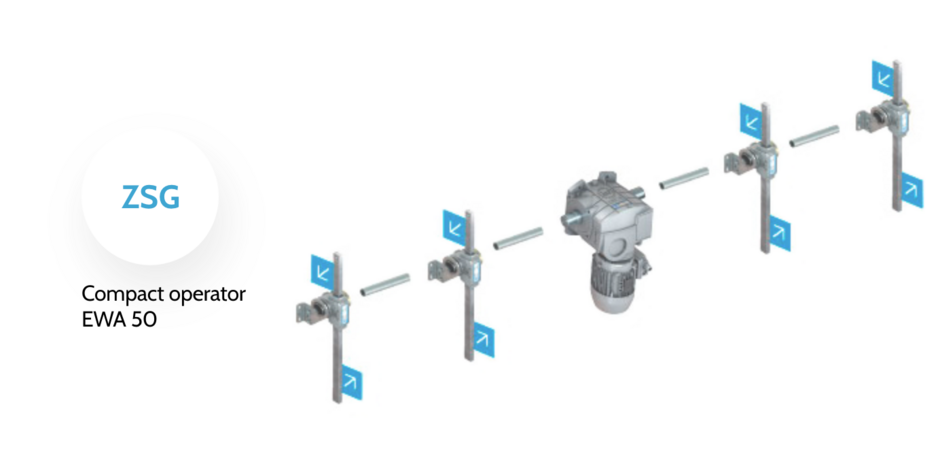

Lock drive systems are used in ventilation systems to automatically adjust the ventilation slats. This enables efficient ventilation of interior spaces, maintaining a pleasant indoor climate. The precise control also supports the energy efficiency approach of modern buildings.

Whether 1,450 m² of louvre bays on the curved glass facade of the Königsbau Passagen in Stuttgart or solar shading and SHEVS on the outstanding Stadtlagerhaus in Hamburg. In both cases, the technicians responsible relied on Lock rack and pinion gearboxes.

The rack and pinion gearboxes, some of which have been newly developed and dimensioned for the objects, impress in all variants with their simple, cost-effective installation, long service life and absolutely reliable mechanical synchronisation.

The features include:

- Extremely robust special rack and pinion gearbox

- Sturdy aluminium housing

- Self-locking worm gear unit

- The original "Made in Germany"

The drive system for sashes and flaps - fulfils individual customer needs:

Lock drive systems are also used in various industrial applications where sashes and flaps need to be moved. This can be in HVAC systems (heating, ventilation, air conditioning) or in industrial processes where precise control over the airflow or other media is crucial.

Bright sunshine, and the sashes or flaps of large glass facades open effortlessly. This is perfectly synchronised thanks to Lock's reliable mechanical couplings. This harmonious interplay of electric drives and rack and pinion gears ensures an optimum user experience. In the versatile Lock modular system, you will find the perfectly matched products that fulfil your individual needs.

The outstanding features of this drive system include:

- extremely robust special rack and pinion gearboxes that can withstand even extreme loads.

- A sturdy aluminium housing for long-lasting reliability.

- Universally applicable to meet the different needs of our customers.